We cover the entire spectrum of ceramic dewatering elements required for paper machines, board machines, pulp machines and tissue machines:

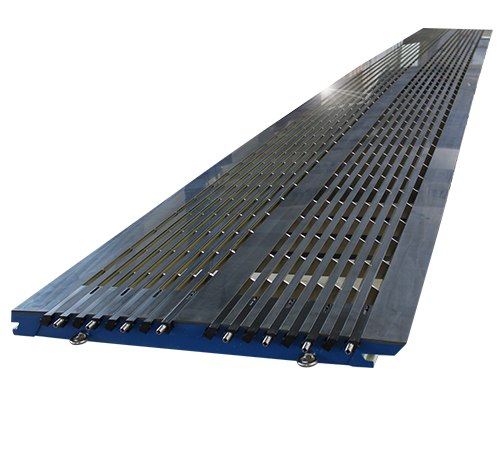

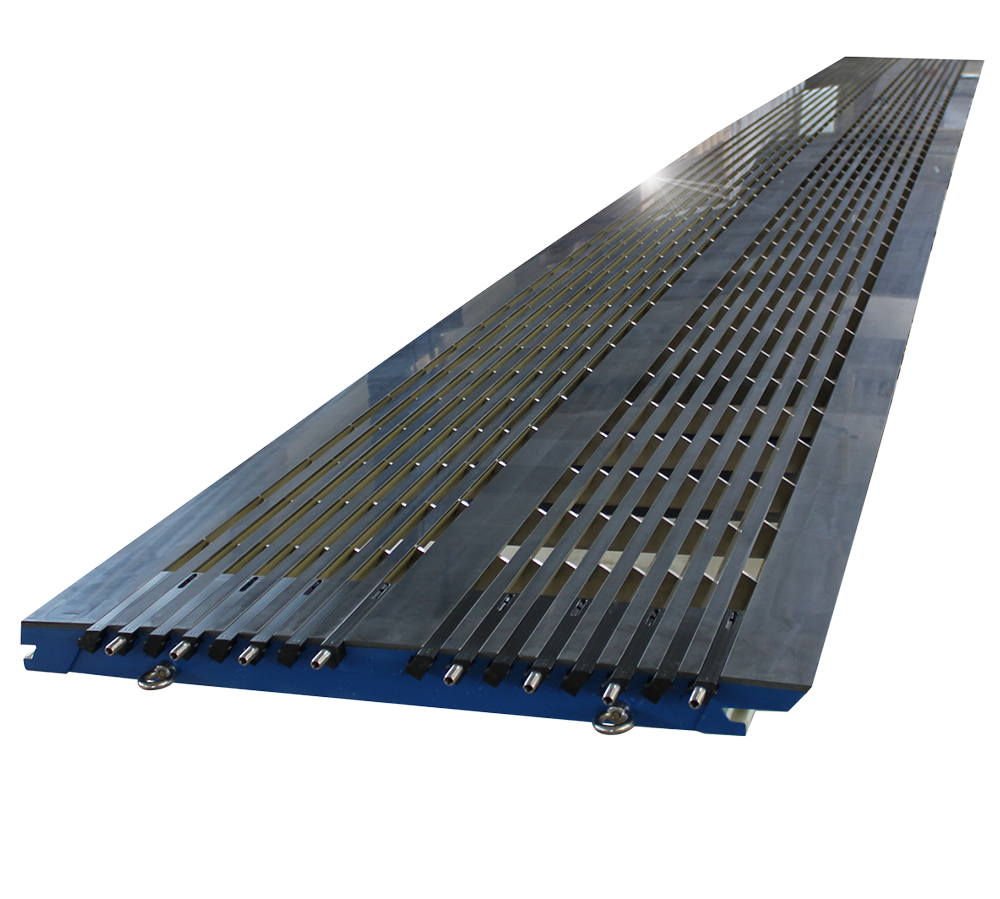

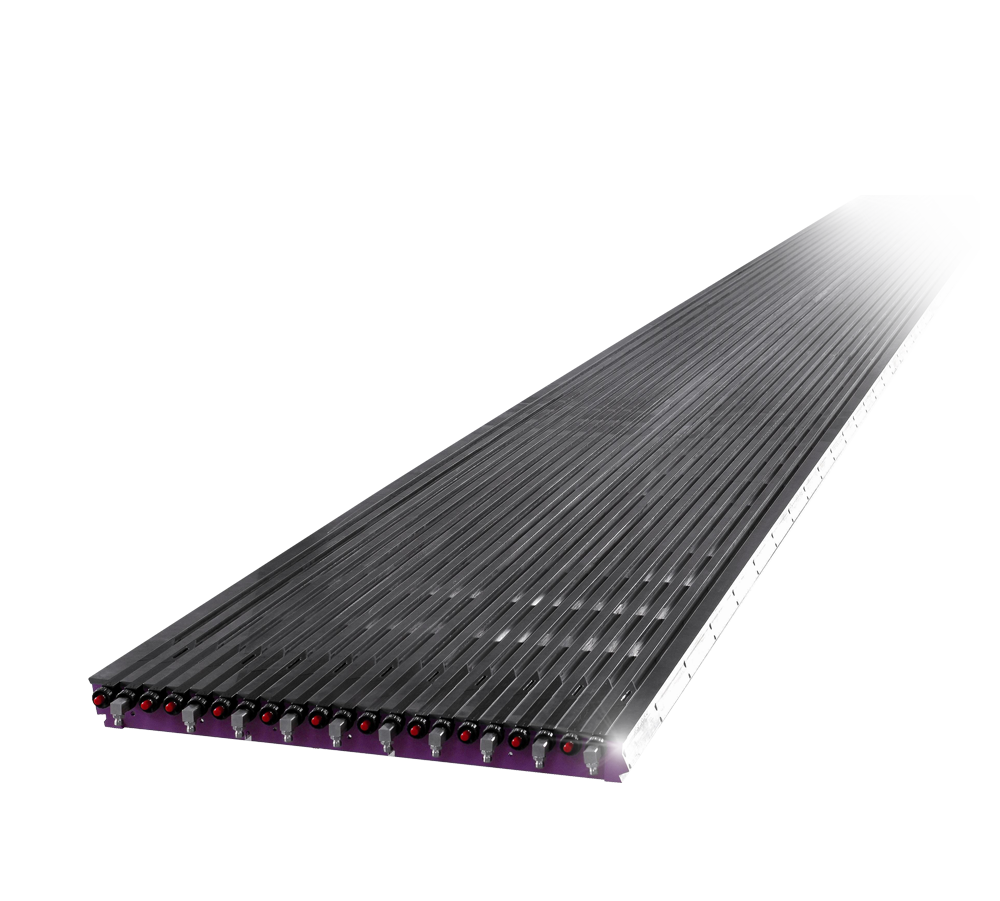

- Forming board blades and covers

- Hydrofoils

- Height-adjustable dewatering blades

- Angle-adjustable dewatering blades

- MTR blades

- VARIOLINE® blades

- Vacufoils

- Wet suction box covers

- Former blades and covers

- Forming blades

- Transfer suction box blades and covers

- Flat suction box covers

- Wire suction box blades

- Felt suction box blades and covers

- Deflector blades

- Edge trim suction box blades and covers

- Drilled covers

- Zig-Zag covers

- More special designs