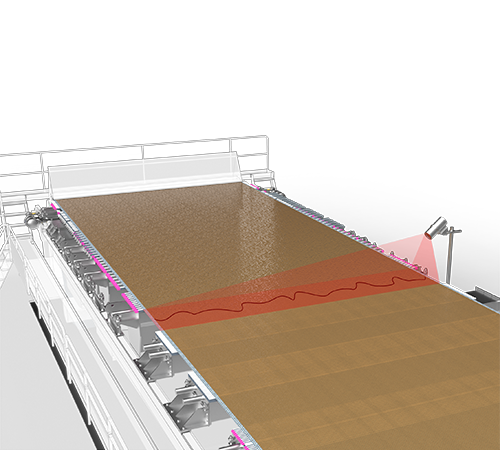

For optimum initial dewatering and sheet forming.

- Save Resources +

-

Products & Solutions

+

- Rebuilds & Performance

- Dewatering technology

- Machine cleaning and doctoring systems

- Vacuum control systems

- Fabric tensioning and guiding systems

- Consumables and wear parts

- Steam showers and rewetting systems

- Reel change systems

- Machine vision solutions

- Stock, additive and starch preparation

- Monitoring and control technology

- Metering systems

-

Safety

- safetyMASTER

- iSAFETY

back

- Edge and trim handling

- Tissue Solutions

- Services +

- About us +

- Careers +

maXX™

OUR RESPONSE TO MASSIVELY INCREASED RAW MATERIAL AND ENERGY COSTS.

Save up to 2 million euros per year in production costs - with the iTABLE® maXX™.

Reduce costs for fibers, starch, steam and electricity now - with maXX™ products.

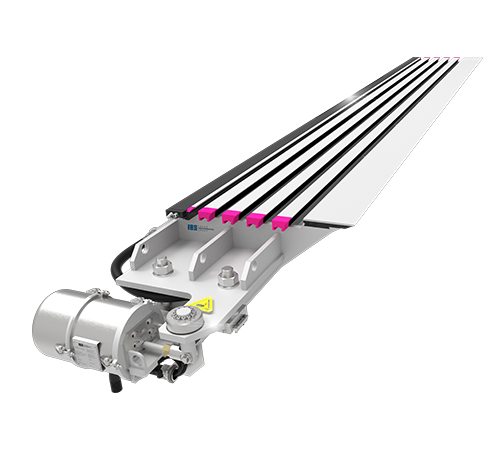

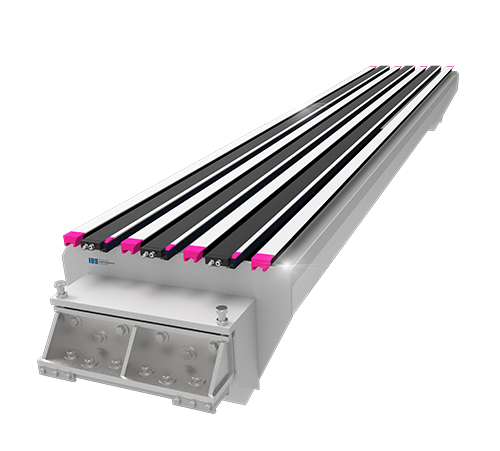

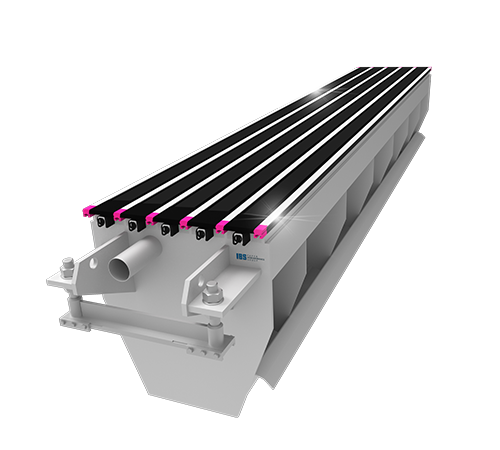

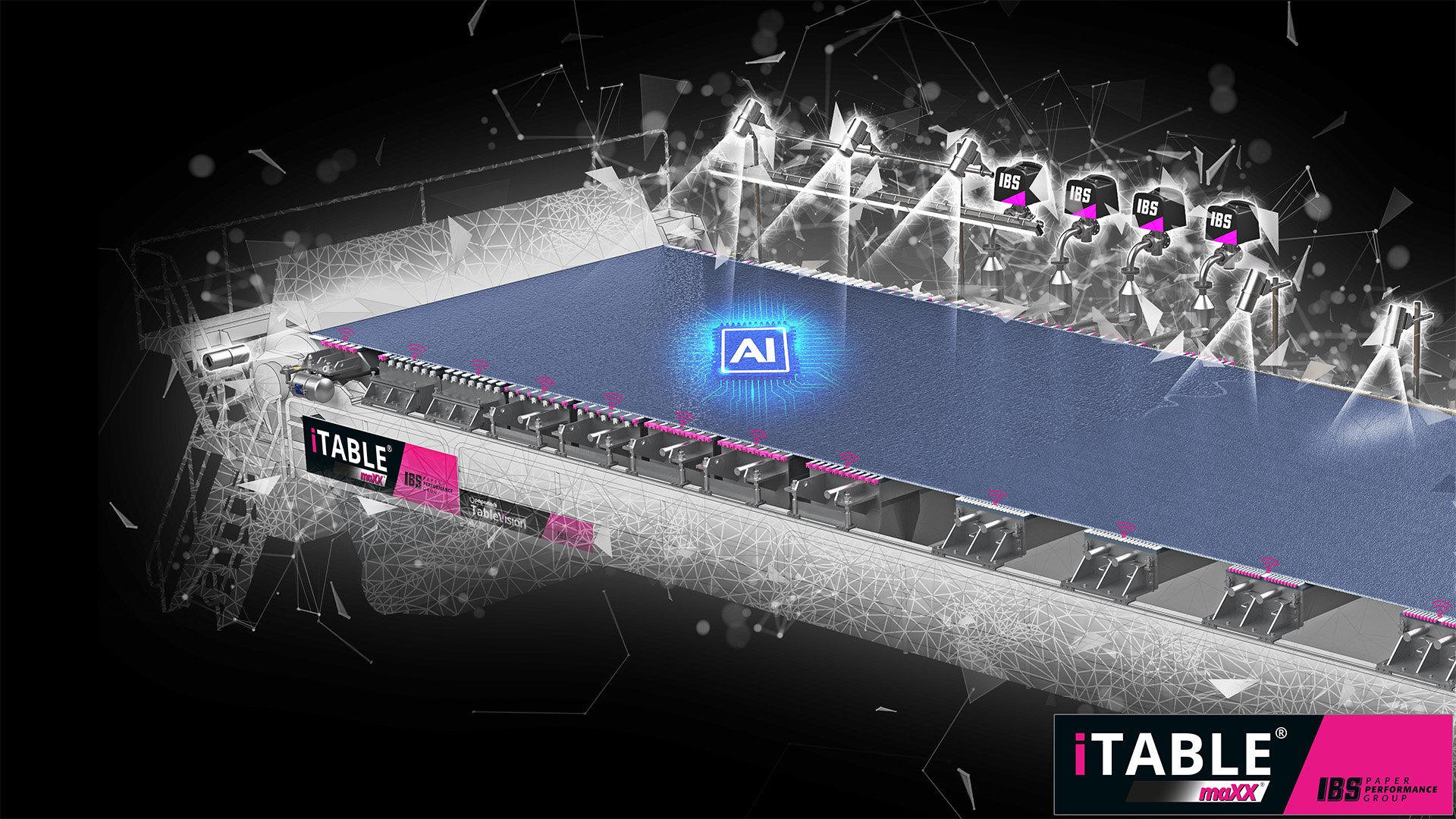

iTABLE® maXX™

The first fully automated sheet forming zone for Fourdrinier machines.

The iTABLE® maXX™ is the world's first fully automated sheet forming zone for Fourdrinier machines and our answer to massively increased raw material and energy costs. The iTABLE® maXX™ combines high-quality and perfectly coordinated products to create an incomparable system solution.

THE ORIGINAL. NEXT LEVEL.

The iTABLE® maXX™ is the next step in the evolution of the iTABLE®. Over 250 successful iTABLE® installations worldwide speak for themselves - papermaking reinvented!

MANY INSTALLATIONS CONFIRM SAVINGS POTENTIAL

Save up to € 2 million per year.

Based on over 250 successful iTABLE® installations worldwide, the iTABLE® maXX™ has been specially developed to specifically reduce the most important cost factors in paper production and thus further maximize operational efficiency. Many installations confirm the immense savings potential.

THE RETURN ON INVESTMENT FOR ALL PROJECTS IS JUST A FEW MONTHS.

FIBERS -15 %

Reduce your fiber costs by up to 15 %.

STARCH -30 %

Reduce your starch costs by up to 30 %.

STEAM -15 %

Reduce your steam costs by up to 15 %.

POWER -20 %

Reduce your electricity costs by up to 20 %.

PRODUCTION +15%

Increase your production quantity by up to 15%.

QUALITY +35%

Improve your paper quality by up to 35%.

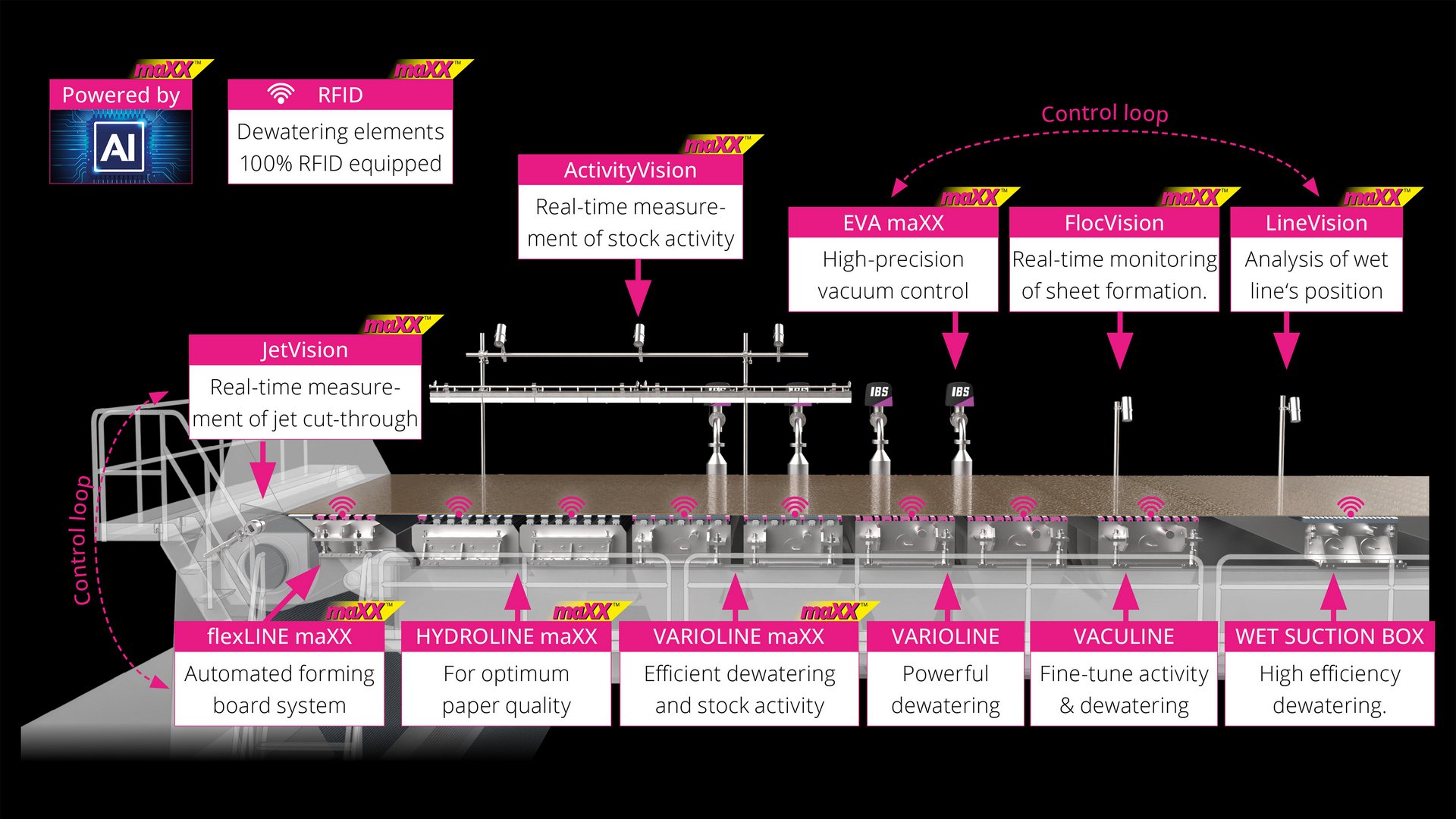

NEW COMPONENTS AND UNIQUE FEATURES

New and perfectly coordinated products enable unique features and shape the iTABLE® maXX™ into an incomparable system solution.

Dewatering systems with ACTIVITY maXX™ - Unique and patented

Our newly developed ACTIVITY maXXTM dewatering blades underscore our claim to be the innovation leader in dewatering technology for paper machines. This unique and patented technology is the ultimate performance boost for our dewatering solutions, which have been tried and tested thousands of times and are continuously being further developed.

Machine Vision solutions as an integral part

Papertech's camera-based solutions for monitoring the jet impingement point, stock activity, sheet formation, and wet line are an integral part of the unique iTABLE® maXXTM. The systems provide crucial data for the intelligent control of components, vacuum, water line, jet impingement point, etc.

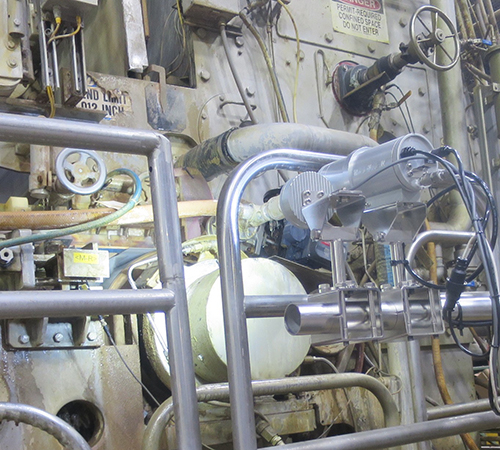

EVA maXXTM and EPB maXXTM vacuum control systems

With EVA maXXTM and EPB maXXTM, we offer completely new vacuum control systems for maximum precision and reliability in vacuum control.

Automation & artificial intelligence

The iTABLE® maXXTM is the first fully automated sheet forming zone for Fourdrinier machines. The system offers intelligent control and works with artificial intelligence.

Dewatering elements 100% equipped with RFID - since 2016

All IBS dewatering elements delivered from 2016 onwards, regardless of whether they are dewatering blades or dewatering covers, are equipped with our RFID chips. This enables us to provide an even better quality of service.

Many more…

Information on other features and products is available on request.

WANT TO FIND OUT YOUR POTENTIAL?

Our experts look forward to a non-binding conversation with you.

Contact us today and schedule a no-obligation 30-minute online consultation with one of our experts. Find out everything you need to know about your individual savings potential with maXXTM.

IBS Austria GmbH

Hauptstraße 22

8833 Teufenbach-Katsch

Austria

Phone: +43 (0) 3582 8511

E-Mail: Send inquiry