Portable camera system to identify root causes of quality defects and web breaks.

- Save Resources +

-

Products & Solutions

+

- Rebuilds & Performance

- Dewatering technology

- Machine cleaning and doctoring systems

- Vacuum control systems

- Fabric tensioning and guiding systems

- Consumables and wear parts

- Steam showers and rewetting systems

- Reel change systems

- Machine vision solutions

- Stock, additive and starch preparation

- Monitoring and control technology

- Metering systems

-

Safety

- safetyMASTER

- iSAFETY

back

- Edge and trim handling

- Tissue Solutions

- Services +

- About us +

- Careers +

REDUCE WEB BREAKS AND BROKE

A KEY TO MORE SUSTAINABILITY WHILE REDUCING COSTS AT THE SAME TIME.

With our solutions, you can produce more sustainably and at lower costs.

At the same time, you achieve the same or even better product quality.

Why should you think about it?

Web breaks and broke waste all previously invested resources.

- Web breaks and broke waste all previously invested resources - from materials to personnel costs.

- In addition, web breaks lead to a quality-restricted start-up phase.

- Irregular machine operation has a negative impact on the entire production line.

- Reducing unplanned downtime leads to more production.

How can we support you in this?

With our know-how, products and solutions, we can help you to reduce web breaks and broke as follows - and all while maintaining or even improving product quality:

- Reduction of unplanned paper breaks and interruptions to save resources to

- achieve a high level of production and

- continuously produce homogeneous product quality.

- Understand the causes of paper breaks in order to avoid them in the future.

- Targeted optimization of machine sections to

- avoid unplanned interruptions and downtime,

- and boost overall machine efficiency.

Success Stories

Below you will find a selection of successfully implemented projects.

All projects presented…

- ... show that it is possible to save resources while reducing production cost.

- ... achieved consistent or even improved product quality.

- ... have a return on investment of a few months only taking into account the overall added value achieved.

- ... have been implemented many times - no prototypes or trial installations.

Web breaks reduced by 40%, additional production secured.

Savings for project implemented by IBS PPG: € 820.000 per year

TARGETS ACHIEVED

- Reduction of web breaks by 40% through improved root cause analysis.

- Increased production due to fewer paper breaks of 8,200 t/a.

- Same or even improved product quality.

- Return on investment within a few months.

Web breaks reduced, run on the winder optimized.

Savings for project implemented by IBS PPG: € 145.000 per year

TARGETS ACHIEVED

- More stable run on the winder.

- No production slow down of entire line.

- Reduction of web breaks as there is no contact marker to web.

- Significantly reduced quality costs due to improved defect detection.

- Savings on ink, no consumable at all.

- Savings on maintenance & spare parts.

- Same or even improved product quality.

- Return on investment within a few months.

Web breaks associated with edge trimming reduced by 85%.

Savings for project implemented by IBS PPG: € 92.000 per year

TARGETS ACHIEVED

- Reduction of paper breaks related to edge trim by 85%.

- This enables additional production of 430 t/a.

- Same or even improved product quality.

- Return on investment within a few months.

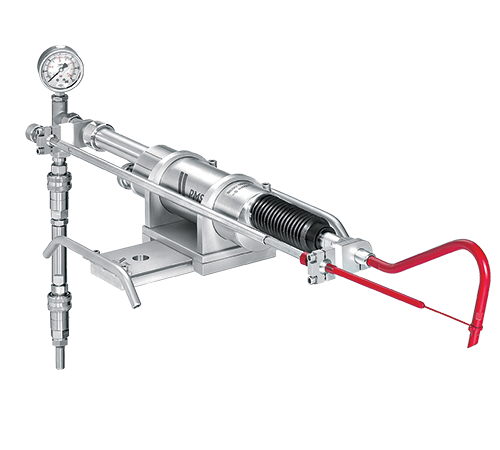

Increased service life of metering rods by 80%.

Production increase for project implemented by IBS PPG: € 195.000 per year

TARGETS ACHIEVED

- Increased service life of metering rods by 80%.

- Approx. 8 metering units less needed per year.

- Decreased number of required metering rod changes => leads to reduced production loss.

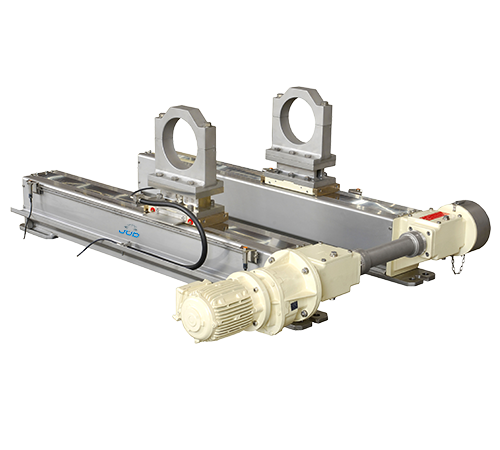

Metering rod change-over time shortened by 50%.

Production increase for project implemented by IBS PPG: € 330.000 per year

TARGETS ACHIEVED

- Metering rod change-over time shortened by 50%.

- Metering rods changed by customer at every paper break.

- Less required metering rod change-over time => leads to reduced production loss.

Machine availability increased, damages to dryer fabric eliminated.

Savings for project implemented by IBS PPG: € 85.000 per year

TARGETS ACHIEVED

- 2 machine stops due to guiding system failure per year eliminated.

- No more damages to dryer fabric.

- Costs for spare parts significantly reduced.

PAPER

EXPERIENCE

IBS Austria GmbH

Hauptstraße 22

8833 Teufenbach-Katsch

Austria

Phone: +43 (0) 3582 8511

E-Mail: Send inquiry