The IBS Paper Performance Group is currently presenting a new, unique product line under the name maXX™. With this move, the world's leading specialist in paper machine optimization is responding to the massive increase in raw material and energy costs in the paper industry.

"Our maXX™ products are the direct answer to the current challenges that significantly affect the profitability of paper producers. The savings potential for our customers is up to 2 million euros annually, with a return on investment of just a few months," says DI Erich Weitgasser, Technical Director of the IBS Group.

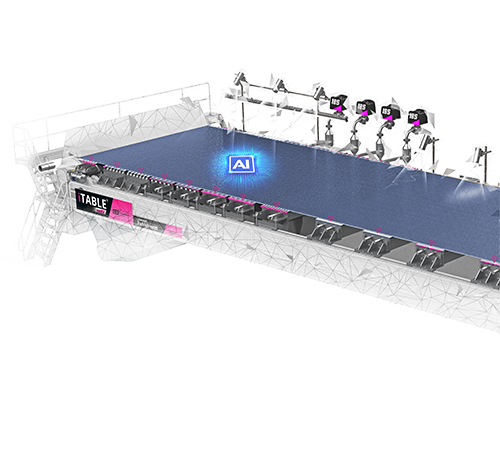

The first fully automated sheet forming zone

The centerpiece of the new product line is the iTABLE® maXX™. The iTABLE® maXX™ is the first fully automated sheet forming zone for fourdrinier machines and the logical further development of the IBS iTABLE®. The iTABLE® maXX™ combines high-quality, perfectly coordinated products to create an unparalleled system solution. For this purpose, the group of companies relies on completely newly developed technologies and products.

Here is just a brief excerpt of the most important innovations:

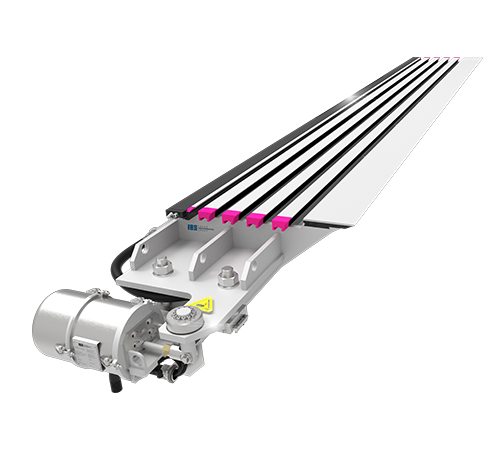

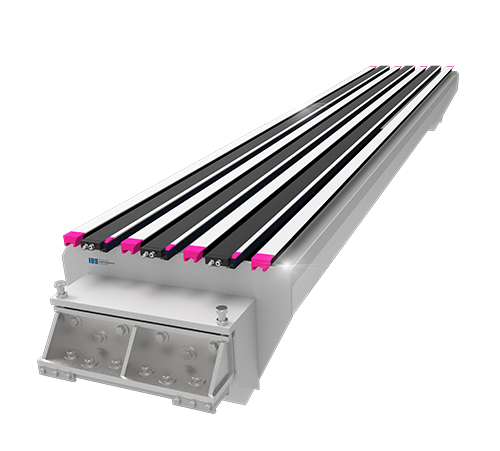

- Dewatering systems with ACTIVITY maXX™

The newly developed and patented ACTIVITY maXXTM dewatering blades underscore the IBS Group's claim to be the innovation leader in dewatering technology for paper machines. This unique technology is the ultimate performance boost for the Austrian group's dewatering solutions, which have been proven thousands of times over and are continuously being further developed. - Machine vision solutions as an integral component

The camera-based solutions from Papertech, a subsidiary of the IBS Group, are an integral component of iTABLE® maXXTM. The innovative systems not only enable the measurement and monitoring of the jet impingement point, stock activity, formation, and wet line. They also provide crucial data for the intelligent control of dewatering components, vacuum, water line, jet impingement point, and much more. - New vacuum control systems

With EVA maXXTM and EPB maXXTM, IBS is also launching completely new versions of its proven vacuum control systems. These offer even greater precision and reliability in vacuum control in both high vacuum and low vacuum applications. - Automation & artificial intelligence

Thanks to the increased availability of data, iTABLE® maXXTM offers a wide range of options for automating various processes. Among other things, artificial intelligence is also used for this purpose. - Dewatering elements 100% equipped with RFID

All dewatering elements delivered by the IBS Group from 2016 onwards, regardless of whether they are dewatering blades or dewatering covers, are equipped with RFID chips. These open up completely new possibilities for servicing the elements.

Installations confirm savings potential

Based on over 250 iTABLE® installations worldwide, the iTABLE® maXX™ was specially developed to specifically reduce the most significant cost factors in paper production and thus further maximize operational efficiency. Experience shows that the return on investment for projects is only a few months. Many installations confirm the immense savings potential:

· FIBERS: Savings potential of up to 15%.

· STARCH: Savings potential of up to 30%.

· STEAM: Savings potential of up to 15%.

· ELECTRICITY: Savings potential of up to 20%.

· PRODUCTION: Increase of up to 15%.

· PAPER QUALITY: Increase of up to 35%.

Audit reveals potential savings

A customized audit by IBS experts is the first step in every project. IBS relies on a global network of experienced experts and paper manufacturers. As part of an audit, the individual savings potential of maXX™ products is assessed for each customer. Audits can be requested directly and without obligation at maxx@ibs-ppg.com.

Find out more: www.ibs-ppg.com/en/maxx

back