Maximize the performance of your wet end.

x

- Save Resources +

-

Products & Solutions

+

- Rebuilds & Performance

- Dewatering technology

- Machine cleaning and doctoring systems

- Vacuum control systems

- Fabric tensioning and guiding systems

- Consumables and wear parts

- Steam showers and rewetting systems

- Reel change systems

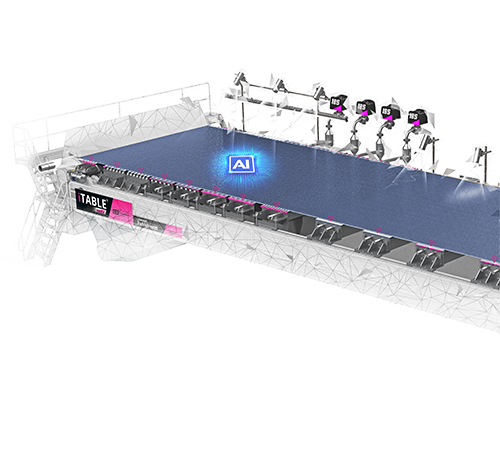

- Machine vision solutions

- Stock, additive and starch preparation

- Monitoring and control technology

- Metering systems

-

Safety

- safetyMASTER

- iSAFETY

back

- Edge and trim handling

- Tissue Solutions

- Services +

- About us +

- Careers +

To overview

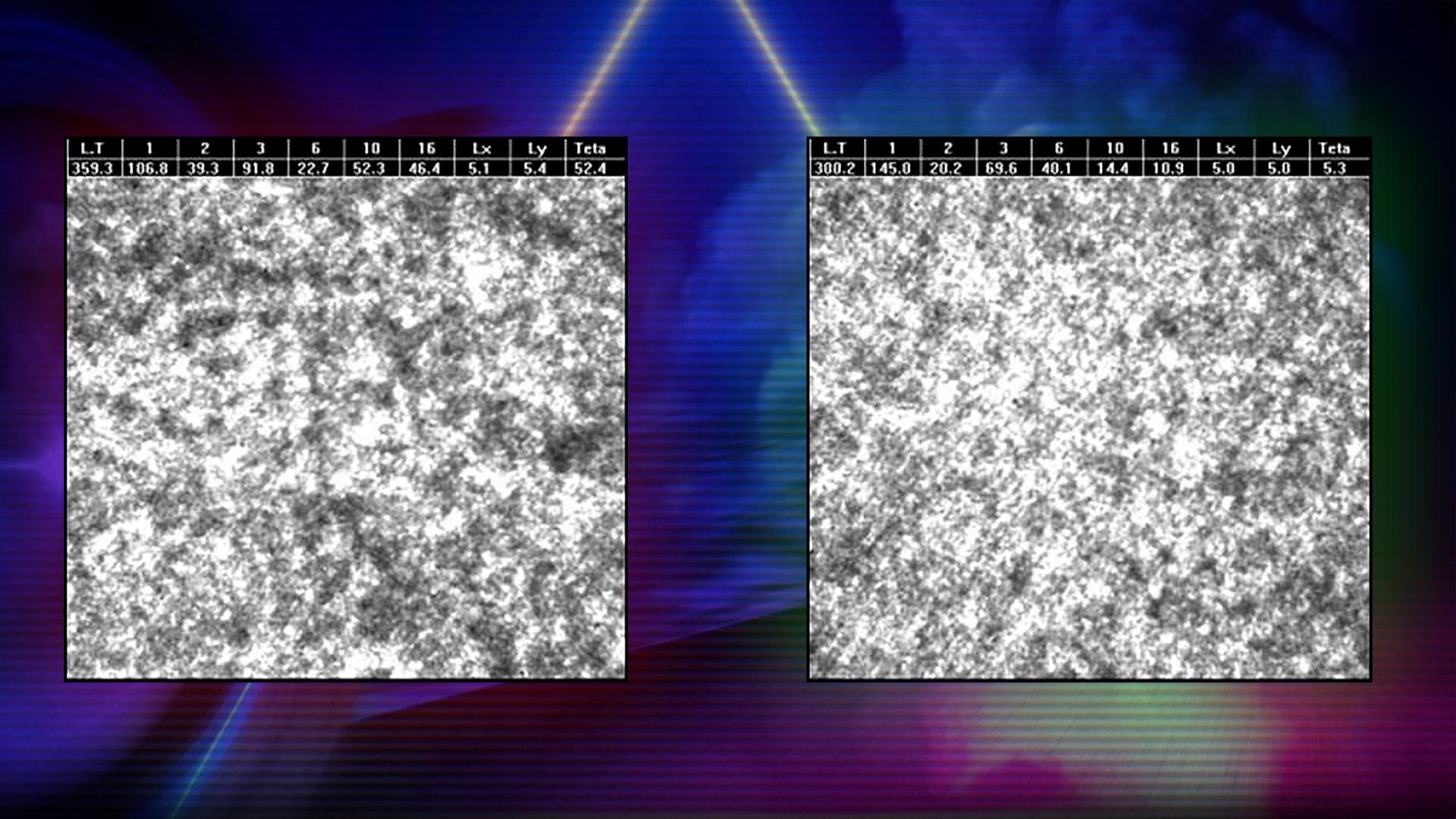

IBS Technology reduces steam consumption by 8% and enables annual savings of EUR 960,000

You could be interested in

IBS of America Corporation

3732 Profit Way

Chesapeake, VA, 23323

USA

Phone: +1 757-485-4210

E-Mail: Send inquiry